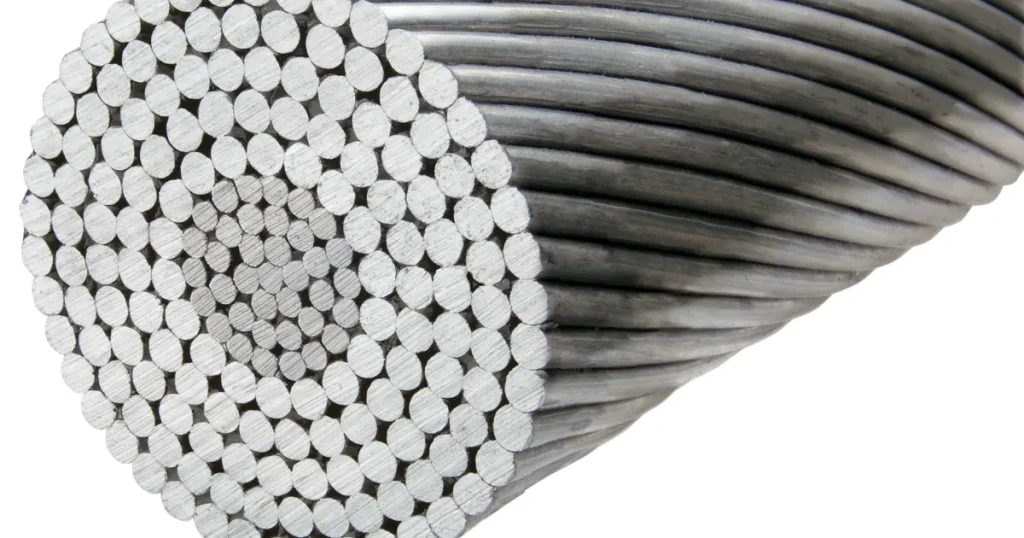

Aluminum is one of the most widely used industrial and commercial metals. Aluminum is usually extracted from bauxite, which is a mineral found in the earth’s crust. In recent years, due to reasons that will be discussed later, aluminum has been able to partially or completely replace steel in many industries. Today, aluminum is widely used in industries such as automobile manufacturing, bicycle manufacturing, construction, and packaging. In this article, we intend to briefly discuss the uses of aluminum in various industries.

What is the uses of aluminum in industries?

One of the factors that makes aluminum suitable for use in many industries is its relatively good strength and its resistance to decay and rust. For this reason, its use in the production of vehicles is very desirable. Of course, it seems necessary to mention that in any case, aluminum is less resilient than steel, so its use in all industries does not seem logical. In any case, this metal gains better resilience and strength at low temperatures. Another disadvantage of using aluminum is its less malleability.

Especially in structures that have a complex shape, the use of aluminum can be very difficult and expensive, if not impossible. In relation to the price of steel and aluminum, due to the instability of the market and different quality levels, it is not possible to give a definite cost, but usually the price of aluminum is calculated to be more expensive than carbon steel.

Transportation industry

Aluminum is used to make many vehicles such as passenger cars, buses and minibuses. Since the weight of aluminum with the same volume is less than steel, using aluminum can in car manufacturing help reduce fuel consumption and make it more efficient. In the vicinity of air, aluminum is covered by a layer of oxide that protects it from corrosion. On the other hand, although aluminum is not as strong as steel, it provides a very good strength-to-weight ratio to car manufacturers. Another point is that aluminum is highly recyclable. Aluminum recycling requires much less energy and cost than its primary production, which can increase productivity in the long run.

Packaging

Aluminum is widely used in the packaging industry. The reason for this is the relative lightness of this material and its good plasticity. Also, aluminum provides very good protection against moisture, air flow and dust. Aluminum is widely used in the beverage industry well. Soft drink cans are usually made of this metal. Also, pharmaceutical packaging and aluminum foils are other uses of aluminum in the packaging industry.

Electronics industry

Since aluminum is considered a very good thermal conductor, this metal is used in many electronic boards that need cooling. Such aluminum is also used in making electrical components. The reason for this is that aluminum can also be a conductor of electricity. Of course, copper still has a very good place in the electronics industry, but due to the cost and excellent corrosion resistance of aluminum, its application has increased.

Household appliance industry

aluminum metal can have a very beautiful appearance if cast properly. For this reason, it is used in many household appliances. Since aluminum has a very high recycling capacity, it can be a good option for household appliances, dishes, furniture and soda cans. Today, aluminum is widely used in the home appliance industry.

What are the positive features of aluminum ?

Light weight

Aluminum has a low density. For this reason, its weight is less compared to many other metals. In general, aluminum weighs one third of steel in the same volume, so when weight is important, aluminum can be very helpful.

Rust resistance

Aluminum oxidizes quickly in the presence of air. But after a thin layer of oxide covers its surface, it can act as a protector and prevent the rest of the layers from rusting. For this reason, it is possible to use aluminum outdoors and in humid environments.

Conductor of heat and electricity

Aluminum is a very good heat and electricity conductor. Therefore, its use is common in electronics and electrical industries.

Strength

Despite its light weight, aluminum has good strength. The ratio of weight to strength of aluminum is very high. For this reason, it can be very logical to use it in situations where both strength and weight are important.

related articles : Brick and its applications in the construction industry

What are the disadvantages of aluminum ?

- Softness: Aluminum is softer than metals like iron or copper. For this reason, it can be vulnerable to dents and scratches. In situations where the friction is high, it will not be logical to use aluminum.

- High cost: considering that the energy consumption of aluminum production is high, the cost of its production may be expensive. therefore, it is not recommended to use it in situations where the final price is very crucial.

- Low melting point: Aluminum has a low melting point compared to other similar metals. As a result, if it is used in a place with high temperature, it may lose its shape and become ineffective.

- Conductor of electricity: As mentioned, aluminum is a conductor of electricity, but its conductivity is significantly lower than that of copper. therefore, where this is of great importance, copper should be used instead.

Last word

Aluminum is one of the most useful metals in the industry for the reasons listed. Industries such as packaging and electronics are increasingly using this metal. Aluminum has unique capabilities and features such as resistance to rust. Of course, unfortunately, in environments that are acidic, this metal wears out quickly and cannot be considered a suitable option.